Quality Control

Qualified examination

To ensure a stable process and thus achieve consistently high quality, detailed knowledge and a great deal of experience are required. Reliable quality control of permanent magnets can only be carried out with the help of sound knowledge in the field of ferromagnetism and the manufacturing processes.

Our employees in China and Germany have many years of experience in magnet production and in the areas of development, purchasing and sales of permanent magnets. Quality monitoring takes place during production, and a further random check of the products is then carried out after delivery.

The head of quality assurance is a certified DGQ auditor.

Measuring technology

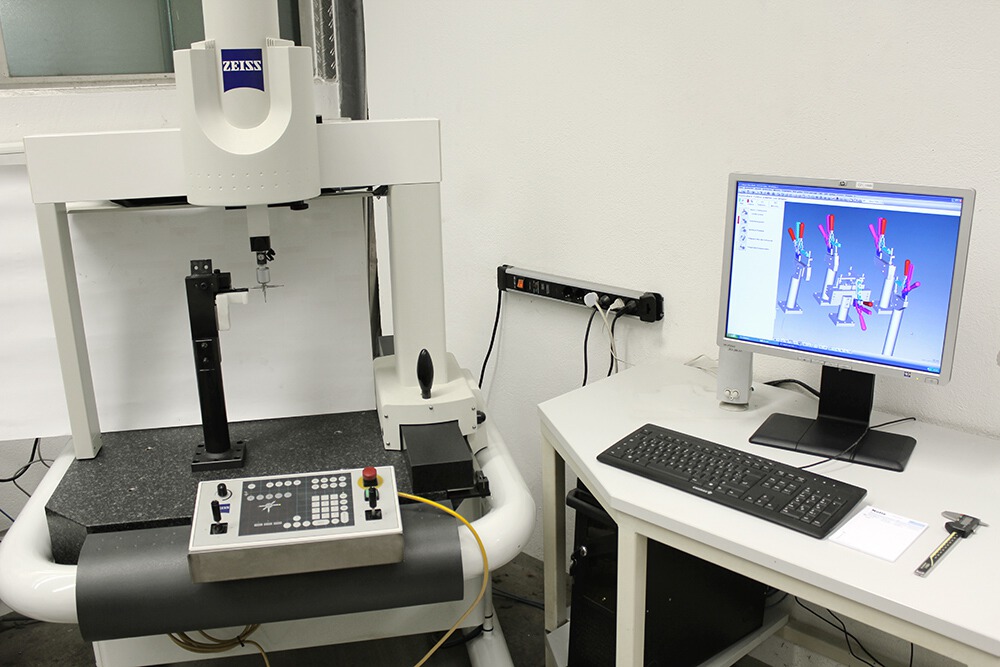

- Zeiss Vista 1620-14

- Hommel T 8000 contour and surface roughness

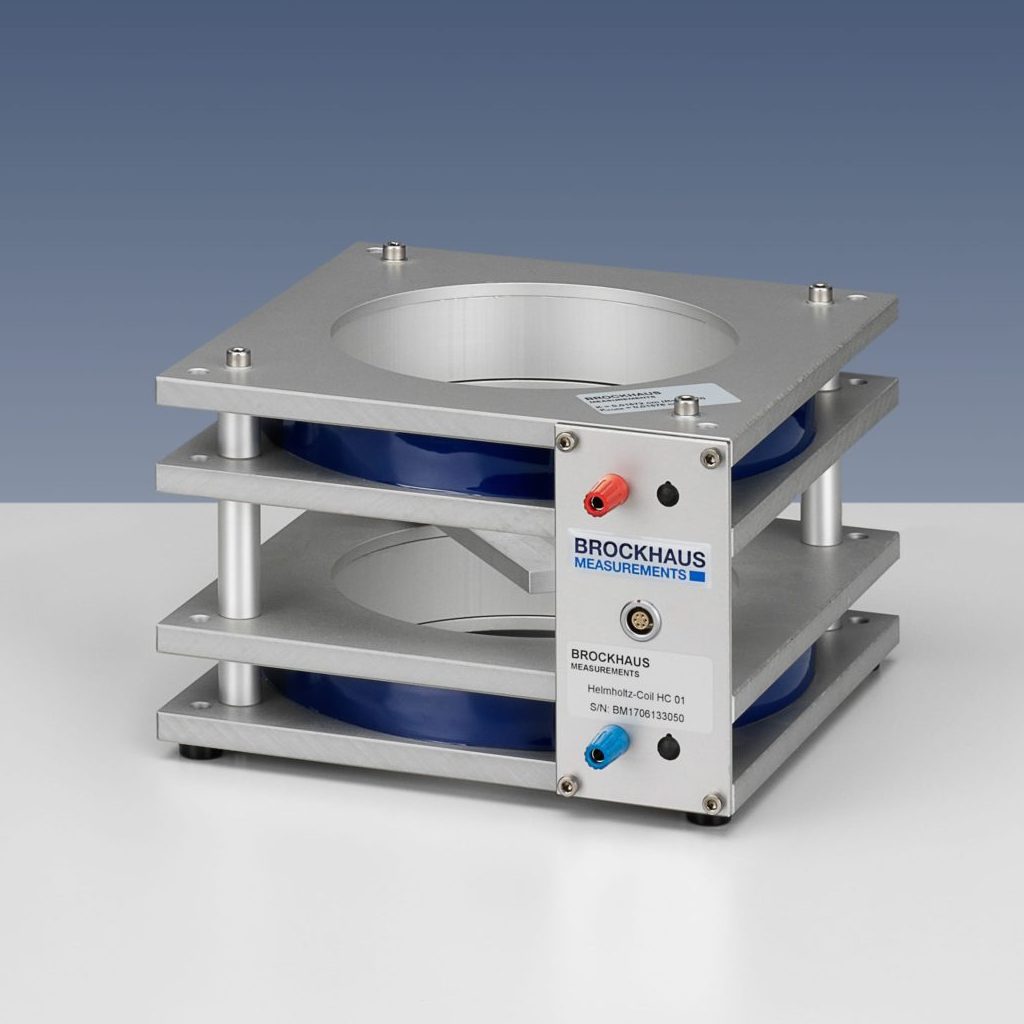

- Brockhaus Helmholtz coils

- Brockhaus flow meter

- Brockhaus Gausmeter

- Magnetization system m-pulse 2k2s

- Steingroever Histograph

- Wild Analysis Microscope

We carry out further investigations in cooperation with renowned institutes and universities (scanning electron microscopy, Squid, vibration magnetometer, Kerr effect microscopy).